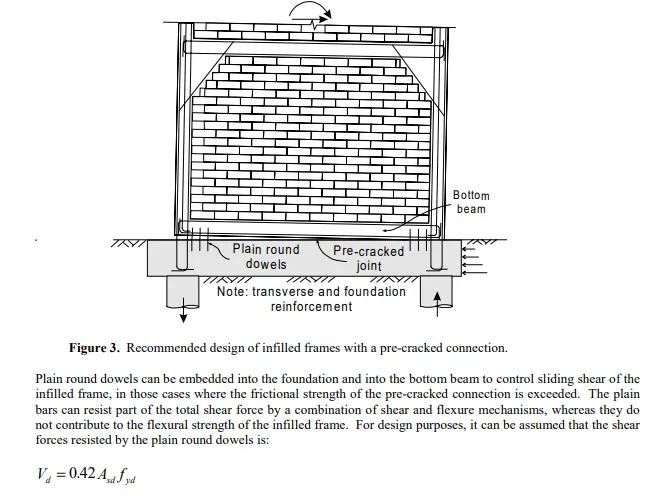

where Asd is the total area of the plain round dowels and fyd is the yield strength. This equation was proposed by Restrepo et al. under the assumption that the shear force in the dowel is transferred by a flexure mechanism, with a distance between plastic hinges equal to the diameter of the dowel. The total area of the dowels, Asd, can be obtained from the previous equation to resist a shear force Vd = Vu – 0.75 Vf (the factor 0.75 is introduced to consider the detrimental effect of cyclic loading in the frictional strength). In order to calculate Vf the coefficient of friction can be adopted as µ = 1.0, considering that the pre-cracked connection is not monolithic concrete.

The plain round dowels should be located in a symmetrical arrangement, preferably along the centre line of the bottom beam, with a separation larger than 15 times the diameter of the dowel. This value is conservatively assumed, in the lack of experimental information, in order to avoid local cracking of the surrounding concrete due to the splitting effect induced by the dowels. The use of several dowels of small diameter could be preferred. The bottom beam has to transfer part of the shear force from the joints of the frame to the dowels. In some cases, depending on the configuration of the infilled frame and on the location of the dowels, tensile axial forces may develop in the bottom beam. This situation should be also considered in the design. Dowel action represents a very flexible mechanism and significant pinching of the hysteresis loops can be expected under cyclic loading. When the lateral forces reverse after significant plastic deformations have developed in the longitudinal reinforcement, the shear has to be entirely transferred by dowel action until contact between the surfaces of the pre-cracked connection is restored. In order to reduce this effect, additional dowels can be placed in the connection to increase the stiffness.

Comments are closed.