The first application of truss type structures is believed to be in Egyptian boats built between 3,100 and 2,700 BC. Egyptian boat builders used trusses constructed by

tying the members together with vines to form the sides and attached the outer hull to these structures (Garrison, 1991). The Romans used wood trusses for bridges and roofs. Examples are a bridge over the Danube (circa 106 AD) and the entrance to the Pantheon (circa 120 AD). The next time frame is that of the Middle Ages. Examples of trusses are found in English cathedrals (Salisbury Cathedral, circa 1258 AD) and great halls (Westminster Palace, circa 1400). Deployment of wooden trusses continued through the Gothic and Renaissance periods, mainly to support roofs. The Engineers of these time periods intuitively understood the rigidity provided by the triangular form, but lacked a theory that they could apply to evaluate the response for a given load.

A major contribution to the theory is the work of Leonardo daVinci (1452–1519), who formulated the concepts of force and moment as vectors and showed that forces can be combined using a graphical construction that is now called the force parallelogram. From the early 1600s to the mid-1800s, many advances in the development of a scientific basis for a theory of structures were made. Key contributors were Newton (1642–1729), Hooke (1635–1703), Galileo Galilei (first useable formula for strength of a cantilever beam-1638), Euler (theory of buckling of columns-1757), Bernoulli (bending deformation of a beam-1741), Navier (produced an integrated theory of Structural Mechanics—1826), and Mobius (published the Textbook of Statics—1837).

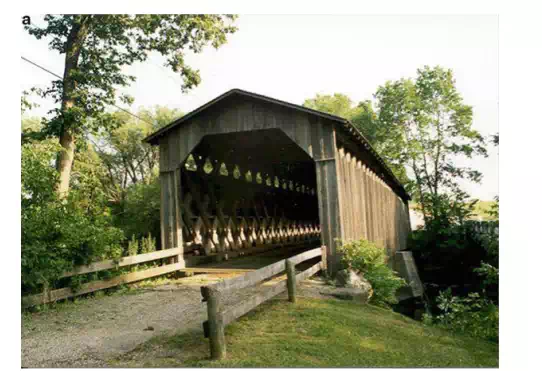

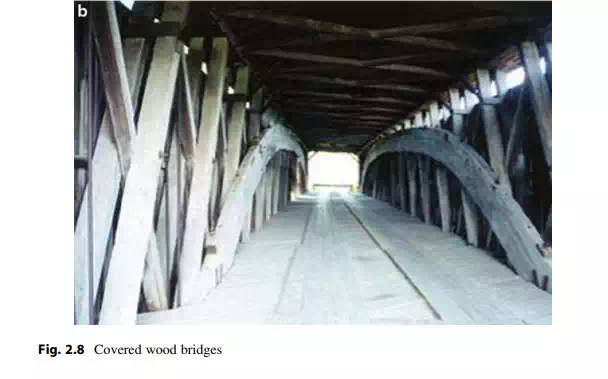

Wooden bridge truss structures were popular in the early 1800s, especially in the USA. There are many examples of covered wooden bridges in Vermont and New Hampshire. Figure 2.8 illustrates some typical structural schemes.

There was a flourishing industry in New England producing wooden bridge trusses, many of which were exported to Europe. As with many emerging technologies, competition from other emerging technologies occurred and eventually took over the market for the product. The first impetus for change was the Industrial Revolution which occurred in the early 1800s. The concept of the railroad

was invented during this period. This invention created a demand for more robust and more durable bridges to carry the heavier moving loads over longer spans. Cost also became an issue. Up to this time, wooden bridges were designed to carry light pedestrian and horse and carriage traffic over relatively short spans. Their expected life was short, but since they used local materials and local labor, they were not expensive and durability was not an issue. However, they were not adequate for the railroad traffic and other solutions were needed.

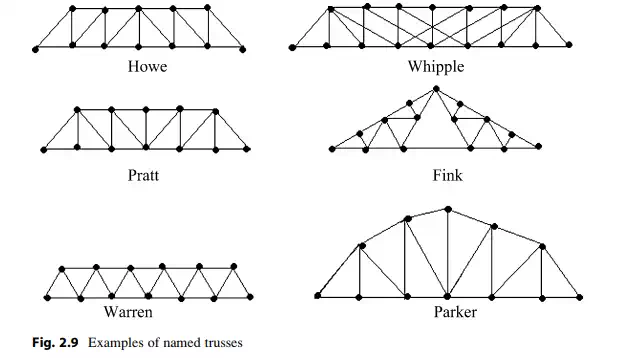

Another technology that was evolving in the late 1700s was iron making. Processes for making cast and wrought iron cheaper than existing methods were developed in the 1780s. Methods for shaping wrought iron into shapes that could be used as truss members were also invented simultaneously. These inventions set the stage for the use of iron members in trusses during the early 1800s. Initially, wrought iron was used for tension elements and wood for compression elements. Gradually, cast iron replaced wood for compression elements. The first all iron truss bridge in the USA was built in 1840 by Squire Whipple, a leading bridge designer in the USA at that time. He is also known for his book Essay on Bridge Building, published in 1847, the first publication on Structural Theory by an US author. Some other designers active in the 1840s were W. Howe, T. Pratt, A. Fink in North America and J. Warren in the UK. Trusses of this era were given the name of the individual who designed or constructed them. Examples are shown in Fig. 2.9.

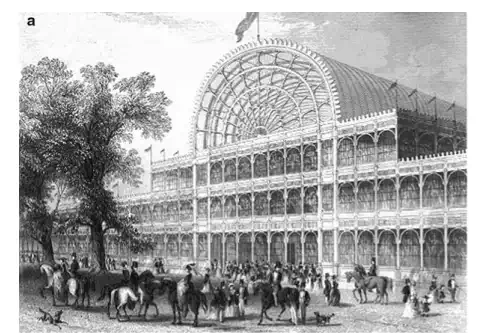

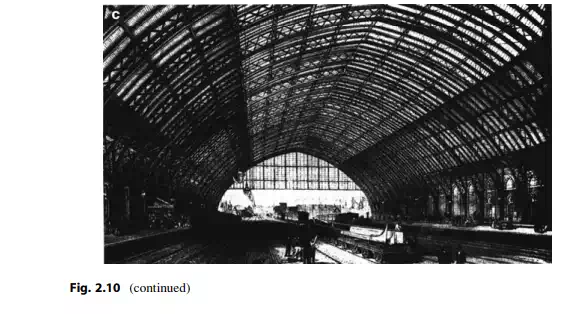

Starting around 1850, iron trusses were used not only for bridges but also for other long-span structures such as market halls, exhibition buildings, and railway stations. Notable examples are the Crystal Palace, the Eiffel tower and the Saint Pancras station (Fig. 2.10).

During the period from1850 to 1870, an improved version of iron called steel was invented. This material was much stronger than cast iron; more ductile than wrought iron, and quickly displaced iron as the material of choice. The first all steel truss bridge in the USA was built for the Chicago and Alton Railroad in 1879. The structure consisted of a series of Whipple trusses with a total length of 1,500 ft spanning over the Mississippi River at Glasgow, Missouri. The first major longspan steel bridge was the Firth of Forth Bridge built in Scotland in 1890. Another similar cantilever style truss bridge was built over the St Lawrence River in Quebec, Canada in 1919. The initial steel structures used eyebars and pins. Rivets replaced pins as connectors in the late 1800s.

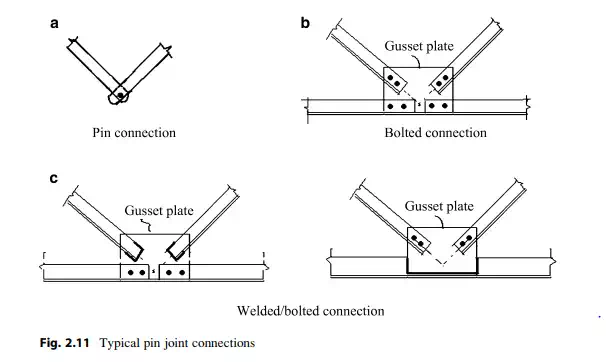

High-strength bolts and welding are now used to connect the structural members in today’s modern steel constructions. Figure 2.11 illustrates typical bolted and welded connections. Connection details are usually designed by the steel fabricator and checked by the structural engineer. The goal in connection design is to minimize steel erection time (Fig. 2.12).

Comments are closed