The characteristics of concrete depend upon the:

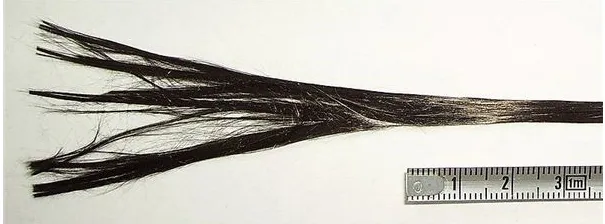

§ type of fiber utilized

§ volume proportion of the fiber

§ ratio of length of the fiber

§ diameter of the fiber

§ dispersal, direction and concentration of fibers

These conditions will improve the mechanical properties, including toughness, ductility, tensile strength, shear resistance and loading limit of the fiber reinforced concrete.

Materials Used for Fiber Reinforcement

Materials used for fiber reinforcement include steel, glass, polyester, rayon, cotton, and polythene. Most commonly used materials are: steel (Steel Fiber Reinforced Concrete) and glass fibers (Glass Fiber Reinforced Concrete or GFRC) that are acid resisting.

Natural fibers being vulnerable to alkali attack are not much popular. Similarly, plastic fibers have recently been introduced in the field of reinforcement and are still in the development phase. It is considered that the contribution of plastic fibers in increasing the static strength of concrete is limited. Nylon fibers have the characteristics of a plastic material, and presently have a limited application in the slab technology. It is generally believed that nylon fibers possess strength that is greater than the welded wire fabric in such slabs.

Asbestos fibers are cheap and have good thermal and mechanical properties that make them suitable for sheet product pipes and tiles. The disadvantage is that they have low impact strength. Carbon fibers are used more and more the last years. They present great elasticity and flexural strength, although they can be damaged easily_._

Comments are closed