Well, what kind of mechanism can achieve this, resisting the gravitational pull of earth? A lubricated sliding surface? Or a strong magnetic levitation? These might sound right but are not the right engineering solution. It should be a system which is capable of restraining the structure under strong gust of winds and gravitational pull. Though an ideal solution is yet to be discovered or invented, there are a few practical isolation mechanisms which are widely used in the field of earthquake engineering. Which means that these systems are capable of reducing the seismic demand of the structure.

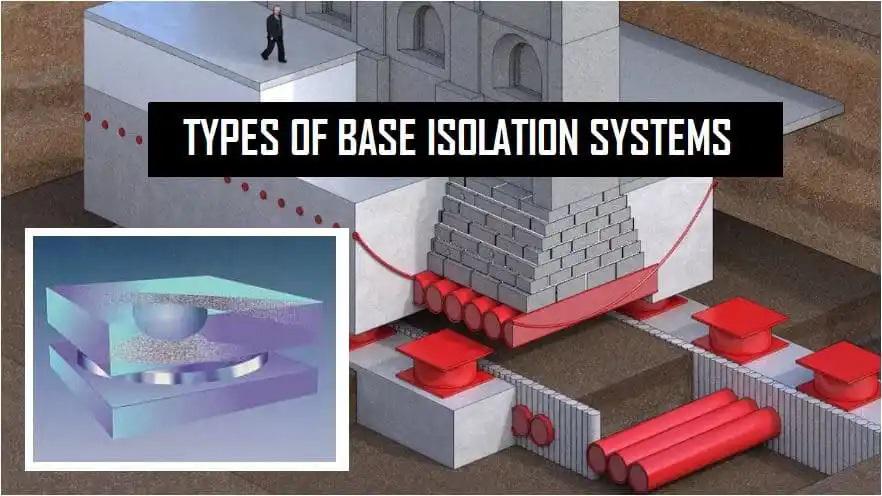

Six major types of Isolators are

Elastomeric Rubber Bearings

Bearings formed of horizontal layers of synthetic or natural rubber in thin layers bound between steel plates. These bearings are capable of supporting high vertical loads with very small deformations. These bearings are flexible under lateral loads. Steel plates prevent the rubber layers from bulging. Lead cores are provided to increase damping capacity as plain elastomeric bearings does not provide significant damping. They are usually soft in horizontal direction and hard in vertical direction.

Elastomeric Rubber Bearings

Roller and Ball Bearings

For isolation applications in machinery isolation, roller and ball bearing are used. It includes cylindrical rollers and balls. It is sufficient to resist service movements and damping depending on the material used.

Roller and Ball Bearings

Springs

Steel springs are most likely used in mechanical applications as in roller bearings. It is not adopted in structural applications because it is flexible in both vertical and horizontal directions. This will increase service deflections.

Spring Isolators

Sliding Bearing

Sliding systems with a predefined coefficient of friction can provide isolation by limiting acceleration and forces that are transferred. Sliders are capable of providing resistance under service conditions, flexibility and force-displacements by sliding movement. Shaped or spherical sliders are often preferred over flat sliding systems because of their restoring effect. Flat sliders provide no restoring force and there are possibilities of displacement with aftershocks.

Sliding Bearing

Soft-story and Sleeved Piles and Rocking Isolation systems are other major systems.

Type of Base Isolation Devices

There are Six major types of base isolation devices which are widely adopted for seismic base isolation.

1. Elastomeric Bearings

2. High Damping Bearings

3. Lead Rubber Bearings

4. Flat Slider Bearings

5. Curved Slider Bearings or Pendulum Bearings

6. Ball & Roller Bearings

Flexibility and Damping are the two major components of base isolation system. Flexibility of the isolation has predominant effect in response modification. Viscous dampers or Hysteretic dampers are often provided to enhance isolation. Response reduction using dampers is independent of the structure stiffness.

Types of Base Isolation System Dampers?

1. Steel Dampers

2. Oil Dampers

3. Lead Dampers

4. Friction Dampers with disc springs

Advantages of Base isolation?

1. Reduced the seismic demand of structure, thereby reducing the cost of structure.

2. Lesser displacements during an earthquake.

3. Improves safety of Structures

4. Reduced the damages caused during an earthquake. This helps in maintaining the performance of structure after event.

5. Enhances the performance of structure under seismic loads.

6. Preservation of property

Isolation reduced the damages caused during an earthquake

Comments are closed