BOLTED SEATED CONNECTIONS

Types of Beam Connections

In general, all beam connections are classified as either framed or seated. In the framed type, the beam is connected to the supporting member with fittings (short angles are common) attached to the beam web. With seated connections, the ends of the beam rest on a ledge or seat, in much the same manner as if the beam rested on a wall.

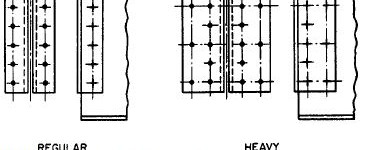

Bolted Framed Connections

When a beam is connected to a support, a column or a girder, with web connection angles, the joint is termed ‘‘framed.’’ Each connection should be designed for the end reaction of the beam, and type, size and strength of the fasteners, and bearing strength of base materials should be taken into account. To speed design, the AISC Manual lists a complete range of suitable connections with capacities depending on these variables. Typical connections for beam or channels ranging in depth from 3 to 30 in are shown in Fig. 7.46.

To provide sufficient stability and stiffness, the length of connection angles should be at least half the clear depth of beam web.

For economy, select the minimum connection adequate for the load. For example, assume an 18-in beam is to be connected. The AISC Manual (ASD) lists three- and four-row connections in addition to the five-row type shown in Fig. 7.46. Total shear capacity ranges from a low of 26.5 kips for 3⁄4-in-diam A307 bolts in a three-row regular connection to a high of 263.0 kips for 1-in-diam A325 bolts in a five-row heavy connection, bearing type. This wide choice does not mean that all types of fasteners should be used on a project, but simply that the tabulated data cover many possibilities, enabling an economical selection. Naturally, one type of fastener should be used throughout, if practical; but shop and field fasteners may be different.

Bearing stresses on beam webs should be checked against allowable stresses (Arts. 7.30.1 and 7.30.2), except for slip-critical connections, in which bearing is not a factor. Sometimes, the shear capacity of the field fasteners in bearing-type connections may be limited by bearing on thin webs, particularly where beams frame into opposite sides of a web. This could occur where beams frame into column or girder webs.

One side of a framed connection usually is shop connected, the other side field connected. The capacity of the connection is the smaller of the capacities of the shop or field group of fasteners.

In the absence of specific instructions in the bidding information, the fabricator should select the most economical connection. Deeper and stiffer connections, if desired by the designer, should be clearly specified.

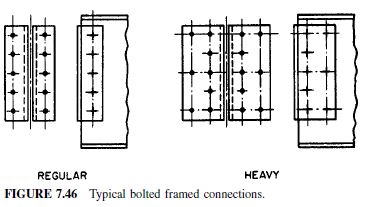

Bolted Seated Connections

Sizes, capacities, and other data for seated connections for beams, shown in Fig. 7.47, are tabulated in the AISC Manual. Two types are available, stiffened seats (Fig. 7.47a) and unstiffened seats (Fig. 7.47b).

Unstiffened Seats. Capacity is limited by the bending strength of the outstanding horizontal leg of the seat angle. A 4-in leg 1 in thick generally is the practical limit.

In ASD, an angle of A36 steel with these dimensions has a top capacity of 60.5 kips for beams of A36 steel, and 78.4 kips when Fy [1] 50 ksi for the beam steel.

Therefore, for larger end reactions, stiffened seats are recommended.

The actual capacity of an unstiffened connection will be the lesser of the bending strength of the seat angle, the shear resistance of the fasteners in the vertical leg, or the bearing strength of the beam web. (See also Art. 7.22 for web crippling stresses.) Data in the AISC Manual make unnecessary the tedious computations of balancing the seat-angle bending strength and beam-web bearing.

The nominal setback from the support of the beam to be seated is 1⁄2 in. But tables for seated connections assume 3⁄4 in to allow for mill underrun of beam length.

Stiffened Seats. These may be obtained with either one or two stiffener angles, depending on the load to be supported. As a rule, stiffeners with outstanding legs having a width less than 5 in are not connected together; in fact, they may be separated, to line up the angle gage line (recommended centerline of fasteners) with that of the column.

The capacity of a stiffened seat is the lesser of the bearing strength of the fitted angle stiffeners or the shear resistance of the fasteners in the vertical legs. Crippling strength of the beam web usually is not the deciding factor, because of ample seat area. When legs larger than 5 in wide are required, eccentricity should be considered, in accordance with the technique given in Art. 7.32. The center of the beam reaction may be taken at the midpoint of the outstanding leg.

Advantages of Seated Connections. For economical fabrication, the beams merely are punched and are free from shop-fastened details. They pass from the punching machine to the paint shed, after which they are ready for delivery. In erection, the seat provides an immediate support for the beam while the erector aligns the connection hole. The top angle is used to prevent accidental rotation of the beam. For framing into column webs, seated connections allow more erection clearance for entering the trough formed by column flanges than do framed connections.

A framed beam usually is detailed to whim 1⁄16 in of the column web.

This provides about 1⁄8 in total clearance, whereas a seated beam is cut about 1⁄2 in short of the column web, yielding a total clearance of about 1 in. Then, too, each seated connection is wholly independent, whereas for framed beams on opposite sides of a web, there is the problem of aligning the holes common to each connection.

Frequently, the angles for framed connections are shop attached to columns.

Sometimes, one angle may be shipped loose to permit erection. This detail, however, cannot be used for connecting to column webs, because the column flanges may obstruct entering or tightening of bolts. In this case, a seated connection has a distinct advantage.

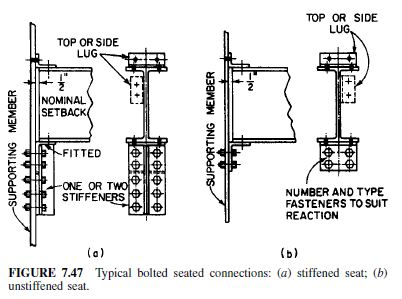

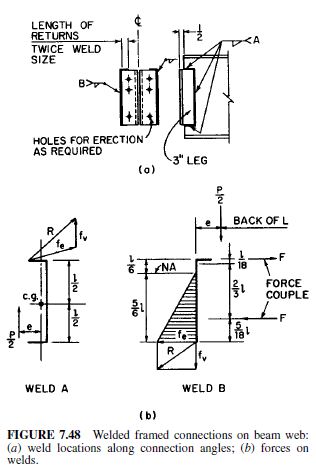

Welded Framed Connections

The AISC Manual tabulates sizes and capacities of angle connections for beams for three conditions: all welded, both legs (Fig. 7.48); web leg shop welded, outstanding leg for hole-type fastener; and web leg for hole-type fastener installed in shop, outstanding leg field welded. Tables are based on E70 electrodes. Thus, the connections made with A36 steel are suitable for beams of both carbon and highstrength structural steels.

Eccentricity of load with respect to the weld patterns causes stresses in the welds that must be considered in addition to direct shear. Assumed forces, eccentricities, and induced stresses are shown in Fig. 7.48b. Stresses are computed as in the example in Art. 7.34, based on vector analysis that characterizes elastic design. The capacity of welds A or B that is smaller will govern design.

If ultimate strength (plastic design) of such connections is considered, many of the tabulated ‘‘elastic’’ capacities are more conservative than necessary. Although AISC deemed it prudent to retain the ‘‘elastic’’ values for the weld patterns, recognition was given to research results on plastic behavior by reducing the minimum beam-web thickness required when welds A are on opposite sides of the web. As a result, welded framed connections are now applicable to a larger range of rolled beams than strict elastic design would permit.

Shear stresses in the supporting web for welds B should also be investigated, particularly when beams frame on opposite side of the web.

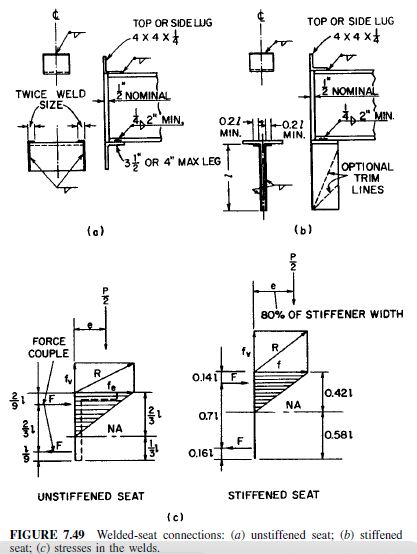

Welded-Seat Connections

Also tabulated in the AISC Manual, welded-seat connections (Fig. 7.49) are the welded counterparts of bolted-seat connections for beams (Art. 7.35.2). As for welded frame connections (Art. (7.35.3), the load capacities for seats, taking into account for eccentricity of loading on welds, are computed by ‘‘elastic’’ vector analysis. Assumptions and the stresses involved are shown in Fig. 7.49c.

In ASD, an unstiffened seat angle of A36 steel has a maximum capacity of 60.5 kips for supporting beams of A36 steel, and 78.4 kips for steel with Fy [1] 50 ksi (Fig. 7.49a). For heavier loads, a stiffened seat (Fig. 7.49b) should be used.

Stiffened seats may be a beam stub, a tee section, or two plates welded together to form a tee. Thickness of the stiffener (vertical element) depends on the strengths of beam and seat materials. For a seat of A36 steel, stiffener thickness should be at least that of the supported beam web when the web is A36 steel, and 1.4 times thicker for web steel with Fy [1] 50 ksi.

When stiffened seats are on line on opposite sides of a supporting web of A36 steel, the weld size made with E70 electrodes should not exceed one-half the web thickness, and for web steel with Fy [1] 50 ksi, two-thirds the web thickness.

Although top or side lug angles will hold the beam in place in erection, it often is advisable to use temporary erection bolts to attach the bottom beam flange to the seat. Usually, such bolts may remain after the beam flange is welded to the seat.

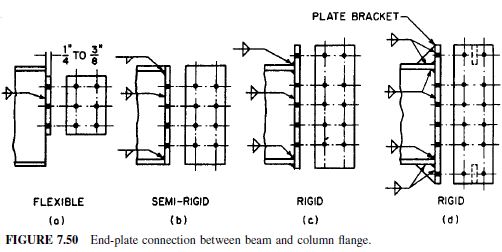

End-Plate Connections

The art of welding makes feasible connections that were not possible with oldertype fasteners, e.g., end-plate connections (Fig. 7.50).

Of the several variations, only the flexible type (Fig. 7.50c) has been ‘‘standardized’’ with tabulated data in the AISC Manual. Flexibility is assured by making the end plate 1⁄4 in thick wherever possible (never more than 3⁄8 in). Such connections in tests exhibit rotations similar to those for framed connections.

The weld connecting the end plate to the beam web is designed for shear. There is no eccentricity. Weld size and capacity are limited by the shear strength of the beam web adjoining the weld. Effective length of weld is reduced by twice the weld size to allow for possible deficiencies at the ends.

As can be observed, this type of connection requires accurate cutting of the beam to length. Also the end plates must be squarely positioned so as to compensate for mill and shop tolerances.

The end plate connection is easily adapted for resisting beam moments (Fig. 7.50b, c and d). One deterrent, however, to its use for tall buildings where column flanges are massive and end plates thick is that the rigidity of the parts may prevent drawing the surfaces into tight contact. Consequently, it may not be easy to make such connections accommodate normal mill and shop tolerances.

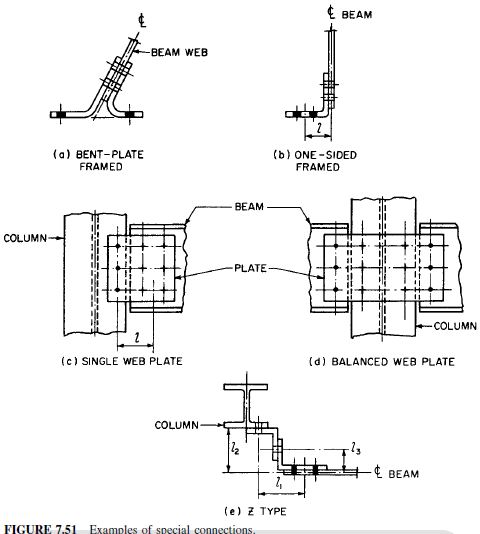

Special Connections

In some structural frameworks, there may be connections in which a standard type (Arts. 7.35.1 to 7.35.5) cannot be used. Beam centers may be offset from column centers, or intersection angles may differ from 90[1], for example.

For some skewed connections the departure from the perpendicular may be taken care of by slightly bending the framing angles. When the practical limit for bent angles is exceeded, bent plates may be used (Fig. 7.51a).

Special one-sided angle connections, as shown in Fig. 7.51b, are generally acceptable for light beams. When such connections are used, the eccentricity of the fastener group in the outstanding leg should be taken into account. Length l may be reduced to the effective eccentricity (Art. 7.32).

Spandrel and similar beams lined up with a column flange may be conveniently connected to it with a plate (Fig. 7.51c and d). The fasteners joining the plate to the beam web should be capable of resisting the moment for the full lever arm l for the connection in Fig. 7.51c. For beams on both sides of the column with equal reactions, the moments balance out. But the case of live load on one beam only must be considered. And bear in mind the necessity of supporting the beam reaction as near as possible to the column center to relieve the column of bending stresses.

When spandrels and girts are offset from the column, a Z-type connection (Fig. 7.51e) may be used. The eccentricity for beam-web fasteners should be taken as l1, for column-flange fasteners as l2, and for fasteners joining the two connection angles as l3 when l3 exceeds 21⁄2 in; smaller values of l3 may be considered negligible.

Simple, Rigid, and Semirigid Connections

Moment connections are capable of transferring the forces in beam flanges to the column. This moment transfer, when specified, must be provided for in addition to and usually independent of the shear connection needed to support the beam reaction.

Framed, seated, and end-plate connections (Arts. 7.35.1 to 7.35.5) are examples of shear connections. Those in Fig. 7.17 (p. 7.32), are moment connections.

In Fig. 7.17a to g, flange stresses are developed independently of the shear connections, whereas in h and i, the forces are combined and the entire connection resolved as a unit.

Moment connections may be classified according to their design function: those resisting moment due to lateral forces on the structure, and those needed to develop continuity, with or without resistance to lateral forces.

The connections generally are designed for the computed bending moment, which often is less than the beam’s capacity to resist moment. A maximum connection is obtained, however, when the beam flange is developed for its maximum allowable stress.

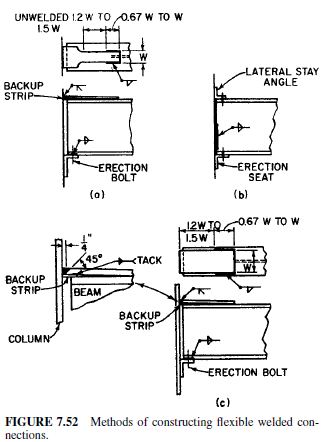

The ability of a connection to resist moment depends on the elastic behavior of the parts. For example, the light lug angle shown connected to the top flange of the beam in Fig. 7.52b is not designed for moment and accordingly affords negligible resistance to rotation. In contrast, full rigidity is expected of the direct welded flange-to-column connection in Fig. 7.52a. The degree of fixity, therefore, is an important factor in design of moment connections.

Fixity of End Connections. Specifications recognize three types of end connections:

simple, rigid, and semirigid. The type designated simple (unrestrained) is intended to support beams and girders for shear only and leave the ends free to rotate under load. The type designated rigid (known also as rigid-frame, continuous, restrained frame) aims at not only carrying the shear but also providing sufficient rigidity to hold virtually unchanged the original angles between members connected.

Semirigid, as the name implies, assumes that the connections of beams and girders possess a dependable and known moment capacity intermediate in degree between the simple and rigid types. Figure 7.54 illustrates these three types together with the uniform-load moments obtained with each type.

Although no definite relative rigidities have been established, it is generally conceded that the simple or flexible type could vary from zero to 15% (some researchers recommend 20%) end restraint and that the rigid type could vary from 90 to 100%. The semirigid types lie between 15 and 90%, the precise value assumed in the design being largely dependent on experimental analysis. These percentages of rigidity represent the ratio of the moment developed by the connection, with no column rotation, to the moment developed by a fully rigid connection under the same conditions, multiplied by 100.

Framed and seated connections offer little or no restraint. In addition, several other arrangements come within the scope of simple-type connections, although they appear to offer greater resistance to end rotations. For example, in Fig. 7.52a, a top plate may be used instead of an angle for lateral support, the plate being so designed that plastic deformation may occur in the narrow unwelded portion. Naturally, the plate offers greater resistance to beam rotation than a light angle, but it can provide sufficient flexibility that the connection can be classified as a simple type. Plate and welds at both ends are proportional for about 25% of the beam moment capacity. The plate is shaped so that the metal across the least width is at yield stress when the stresses in the wide portion, in the butt welds, and in the fillet welds are at allowable working values. The unwelded length is then made from 20 to 50% greater than the least width to assure ductile yielding. This detail can also be developed as an effective moment-type connection.

Another flexible type is the direct web connection in Fig. 7.52b. Figured for shear loads only, the welds are located on the lower part of the web, where the rotational effect of the beam under load is the least. This is a likely condition when the beam rests on erection seats and the axis of rotation centers about the seat rather then about the neutral axis.

Tests indicate that considerable flexibility also can be obtained with a property proportioned welded top-plate detail as shown in Fig. 7.52c without narrowing it as in Fig. 7.52a. This detail is usually confined to wind-braced simple-beam designs.

The top plate is designed for the wind moment on the joint, at the increased stresses permitted for wind loads.

The problem of superimposing wind bracing on what is otherwise a clear-cut simple beam with flexible connections is a complex one. Some compromise is usually effected between theory and actual design practice. Two alternatives usually are permitted by building codes:

1. Connections designed to resist assumed wind moments should be adequate to resist the moments induced by the gravity loading and the wind loading, at specified increased unit stresses.

2. Connections designed to resist assumed wind moments should be so designed that larger moments, induced by gravity loading under the actual condition of restraint, will be relieved by deformation of the connection material.

Obviously, these options envisage some nonelastic, but self-limiting, deformation of the structural-steel parts. Innumerable wind-braced buildings of riveted, bolted, or welded construction have been designed on this assumption of plastic behavior and have proved satisfactory in service.

Fully rigid, bolted beam end connections are not often used because of the awkward, bulky details, which, if not interfering with architectural clearances, are often so costly to design and fabricate as to negate the economy gained by using smaller beam sections. In appearance, they resemble the type shown in Fig. 7.17 for wind bracing; they are developed for the full moment-resisting capacity of the beam.

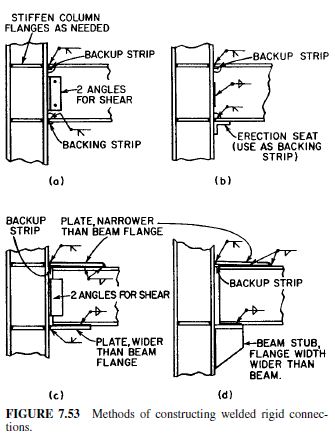

Much easier to accomplish and more efficient are welded rigid connections (Fig. 7.53). They may be connected simply by butt welding the beam flanges to the columns—the ‘‘direct’’ connection shown in Fig. 7.53a and b. Others may prefer the ‘‘indirect’’ method, with top plates, because this detail permits ordinary mill tolerance for beam length. Welding of plates to stiffen the column flanges, when necessary, is also relatively simple.

In lieu of the erection seat angle in Fig. 7.53b, a patented, forged hook-and-eye device, known as Saxe erection units, may be used. The eye, or seat, is shop welded to the column, and the hook, or clip, is shop welded to the underside of the beam bottom flange. For deep beams, a similar unit may be located on the top flange to prevent accidental turning over of the beams. Saxe units are capable of supporting normal erection loads and deadweight of members; but their contribution to the strength of the connection is ignored in computing resistance to shear.

A comparison of fixities intermediate between full rigidity and zero restrain in Fig. 7.54 reveals an optimum condition attainable with 75% rigidity; end and centerspan moments are equal, each being WL/ 16, or one-half the simple-beam moment.

The saving in weight of beam is quite apparent.

Perhaps the deterrent to a broader usage of semirigid connections has been the proviso contained in specifications: ‘‘permitted only upon evidence that the connections to be used are capable of resisting definite moments without overstress of the fasteners.’’ As a safeguard, the proportioning of the beam joined by such connections is predicated upon no greater degree of end restraint than the minimum known to be effected by the connection. Suggested practice, based on research with welded connections, is to design the end connections for 75% rigidity but to provide a beam sized for the moment that would result from 50% restraint; i.e., WL/ 12.

(‘‘Report of Tests of Welded Top Plate and Seat Building Connections,’’ The Welding Journal, Research Supplement 146S–165S, 1944.) The type of welded connection in Fig. 7.52c when designed for the intended rigidity, is generally acceptable.

End-plate connections (Fig. 7.50) are another means of achieving negligible, partial, and full restraint.

Comments are closed