Welding consists of joining two steel sections by means of metallurgical bond between them by the application of pressure and/or fusion.

When two members are connected by means of welds, such a connection is known as welded connection. Welding offers an opportunity to the designer to achieve a more efficient use of the materials. Earlier designers considered welds as less fatigue resistant. It was believed that attaining good welds at site is impossible. Now a day, with the advances in the field of non destructive testing methods (NDT), testing and quality control of welds became easier. This gives the designers enough courage to explore the possibilities and capabilities of welded connections. Speedy construction is facilitated by using welded connections. Weight of welded connections is relatively low and hence cuts cost of construction. Since there is no reduction of holes the gross cross section is effective in carrying loads.

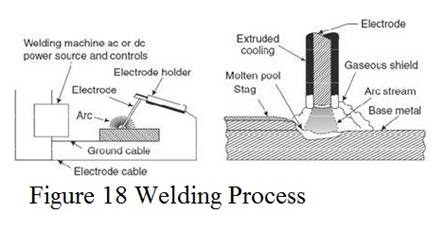

WELDING PROCESS

Welding consists of joining two steel sections by means of metallurgical bond between them by the application of pressure and/or fusion. The most commonly used welding process is fusion process. The bond is produced, in fusion process, by melting the surfaces to be joined and then allowing them to solidify in to a single joint. The most commonly used welding process is the arc welding process (Figure 18). In this process intense heat required (around 36000C) to melt the steel sections is produced by an electric arc. The tremendous heat at the tip of the electrode melts the base metal and the filler metal to form a pool of molten metal called crater which solidifies on cooling produce the joint required.

Comments are closed