Coning of wheels is a method of beveling the wheels to avoid depreciation to the wheels and rims. Normally the wheels are conned by a cone of semi-angle. It is based on the theorem of coning. Read on to get more idea…………

Introduction

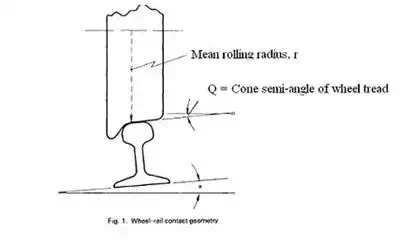

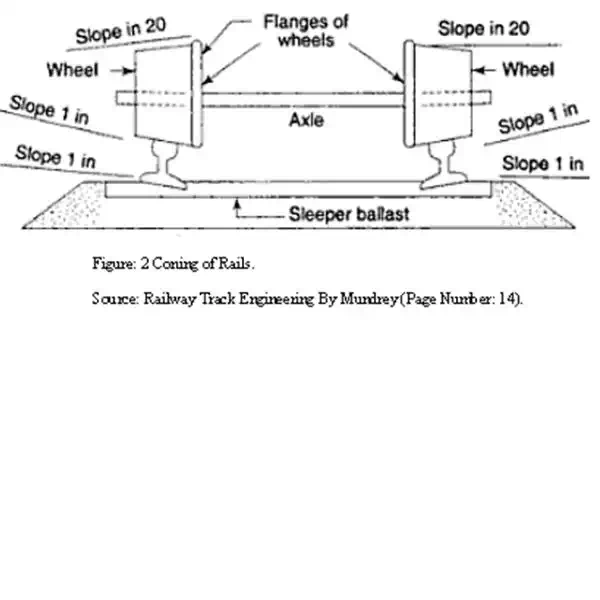

Railway wheels are usually beveled by means of a cone semi-angle of the arrangement of 1/20 (rad.). The rails are also fixed at this identical angle to the perpendicular. The width of the wheel is generally 140 mm and the rail top is approximately 80 mm. The proportions of the region of liaison between an encumbered wheel and rail reckon on the exact shapes of the wheel pace and rail head. It also depends on the extent of the load occupied.

Images

Coning of Wheels

The space between the inner borders of wheel rims is by and large kept less than the measurement of the track. This results in a gap between the wheel rims and running ends of the rails which is approximately equal to 1 cm, (3/8) on both side. More often than not, the tread of wheels is perfectly the dead centre of the beginning of the rail, since the wheel is chamfered to keep it in this middle position involuntarily. Thus the wheels are beveled at an inclination of 1 in 20.

Advantages of coning the wheels

(i) Coning the wheels reduces the depreciation of the wheel rims and rails. Depreciation is caused because of the friction action of rims with inner faces of the rail top.

(ii) Coning also gives an option of lateral drift of the hinge with is wheels.

(iii) Coning also prevents, to some extent, the slipping of the wheels.

Images

Theory of Coning

On a railway level track, the moment the hinge loco motes towards one rail, the wheel tread width above the rail steps-up but reduces over the other rail. This forbids the auxiliary movement and hinge pulls back to its original position. This is possible only if the diameters on both rails are equal and the pressure on both the rails is also equal.

On a coiled path, because of rigidity of the wheel bottom either of the wheels has to slip by a measure equal to the differentiation of length or else the axle has to move outward a bit so that a tread with longer diameter is formed over the outer rail whereas a slighter diameter tread is formed over the inner rail.

If the diameter of the tread on both the rails is equal, then:

Calculation

Slip = Θ(R2 –R1)

The outer Radius, R2 = R=C/2

Inner Radius, R1=R=G/2

G =Gauge

Railway Track

Θ= Angle at centre in radians

Therefore Slip = Θx G

For B.G.track; G = 1.676 meters

and Slip = 2ΠΘ°/360 x 1.676

Where Θ° = angle centre in degrees about 1°

ΘSlip = 029 (roughly for 1° of central angel)

(Source: A Text Book of Railway Engineering by S.C.Saxena and S.P.Arora, Page 3.9)

Therefore, the slip is about. 029 m per degree of central angle.

Chamfering of wheels on bends is not useful as the principal axle if owing to centrifugal force proceeds towards the outward rail the back axle will precede towards the inside rail and the complete benefit of coning wheels cannot be availed. Put differently, there will be no free sidelong movement of wheels. This results in the following disadvantages:

(i) The outer rail will have more pressure while the inner rail will have lesser pressure.

(ii) Owing to the centrifugal strength, the parallel components incline to turn the rail out and gauge has broadening tendency.

(iii) Due to this condition if the voids sleepers have no base plate beneath the edge of the rail they will be damaged.

Conclusion

In order to get rid of or minimise the supra mentioned faults “angling of rails” is done. When the rails are tilted then the base plate or sleeper is not placed horizontal. It is laid at a slope of 1 in 20 towards the inner side. This is known as “adzing of sleepers” which means that the timbers are dressed roughly with an ax like tool.

Comments are closed