Effect of Fibers Utilized with Concrete

Fiber reinforced concrete is a composite material comprised of Portland cement, aggregate, and fibers. Normal unreinforced concrete is brittle with a low tensile strength and strain capacity. The function of the irregular fibers distributed randomly is to fill the cracks in the composite. Fibers are generally utilized in concrete to manage the plastic shrink cracking and drying shrink cracking. They also lessen the permeability of concrete and therefore reduce the flow of water. Some types of fibers create greater impact, abrasion and shatter resistance in the concrete. Usually fibers do not raise the flexural concrete strength. The quantity of fibers required for a concrete mix is normally determined as a percentage of the total volume of the composite materials. The fibers are bonded to the material, and allow the fiber reinforced concrete to withstand considerable stresses during the post-cracking stage. The actual effort of the fibers is to increase the concrete toughness.

Steel Fiber Reinforced Concrete and Applications

During recent years, steel fiber reinforced concrete has gradually advanced from a new, rather unproven material to one which has now attained acknowledgment in numerous engineering applications. Lately it has become more frequent to substitute steel reinforcement with steel fiber reinforced concrete. The applications of steel fiber reinforced concrete have been varied and widespread, due to which it is difficult to categorize. The most common applications are tunnel linings, slabs, and airport pavements.

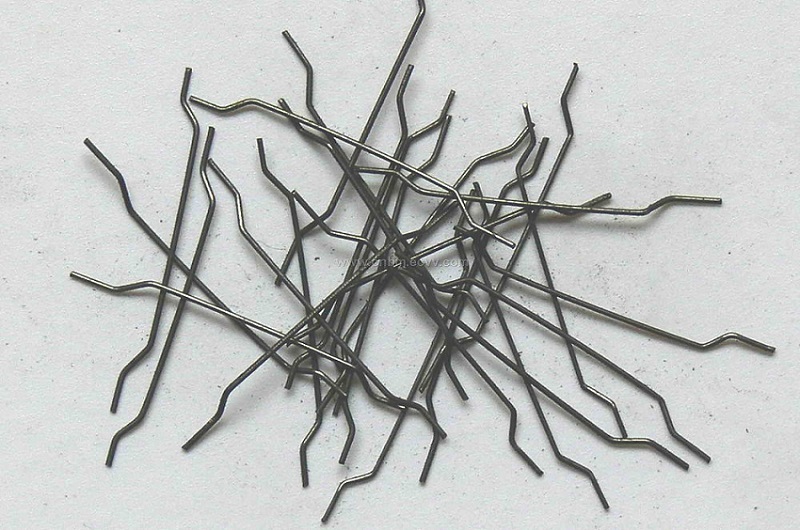

Many types of steel fibers are used for concrete reinforcement. Round fibers are the most common type and their diameter ranges from 0.25 to 0.75 mm. Rectangular steel fibers are usually 0.25 mm thick, although 0.3 to 0.5 mm wires have been used in India. Deformed fibers in the form of a bundle are also used. The main advantage of deformed fibers is their ability to distribute uniformly within the matrix.

Fibers are comparatively expensive and this has limited their use to some extent.

Properties of Concrete Improved by Steel Fibers

Below are some properties that the use of steel fibers can significantly improve:

§ Flexural Strength: Flexural bending strength can be increased of up to 3 times more compared to conventional concrete.

§ Fatigue Resistance: Almost 1 1/2 times increase in fatigue strength.

§ Impact Resistance: Greater resistance to damage in case of a heavy impact.

§ Permeability: The material is less porous.

§ Abrasion Resistance: More effective composition against abrasion and spalling.

§ Shrinkage: Shrinkage cracks can be eliminated.

§ Corrosion: Corrosion may affect the material but it will be limited in certain areas.

Limitations Of Steel Fiber Reinforced Concrete

Though steel fiber reinforced concrete has numerous advantages, it has certain concerns that are yet to be resolved completely.

§ There are complications involved in attaining uniform dispersal of fibers and consistent concrete characteristics.

§ The use of SFRC requires a more precise configuration compared to normal concrete.

§ Another problem is that unless steel fibers are added in adequate quantity, the desired improvements cannot be obtained.

However, as the quantity of fibers is increased, the workability of the concrete is affected. Therefore, special techniques and concrete mixtures are used for steel fibers. If proper techniques and proportions are not used, the fibers may also cause a finishing problem, with the fibers coming out of the concrete.

Comments are closed