1. Compressive strength. The behaviour of thin ferro cement element under compression primarily is controlled by the properties of cement mortar matrix. Its compressive strength varies from 27.5 to 60 MPa.

2. Tensile strength. The tensile strength of ferro cement depends mainly on the volume of reinforcement in the direction of force and the tensile strength of the mesh. The ultimate tensile strength is 34.5 MPa and allowable tensile stress is taken as 10.0 MPa.

The tensile behaviour may be divided into three groups:

1. Pre cracking stage.

2. Post cracking stage.

3. Post yielding stage.

A ferro cement member subjected to increasing tensile stresses behaves like a liner elastic material till the development of first crack in the matrix. Once the cracks are developed, the material enters the stage, of multiple cracking and this stage continues upto the point where wire mesh starts to yield.

In this stage numbers of cracks go on increasing with the increase in tensile stress without any significant increase in the width of the crack. With the yield of reinforcement, the mortar enters the stage of crack widening. At this stage the number of cracks remains constant, but the width of crack go on increasing. The behaviour mainly is controlled by the reinforcement bars.

Fatigue Strength:

The fatigue behaviour of ferro cement flexural elements is governed by the tensile fatigue properties of mesh like reinforced and pre stressed concrete beams. The fatigue strength of ferro cement is poor under cyclic loading.

Impact Strength:

The impact strength of ferro cement has been found to increase linearly with the increase of specific surface (volume fraction) and ultimate strength of mesh reinforcement. Further for the same reinforcement fraction, the element having welded wire mesh reinforcement showed highest impact strength while chicken mesh reinforced section showed lowest impact strength. The impact strength of woven mesh reinforced ferro cement is found higher than chicken wire mesh and lower than welded wire mesh reinforced elements.

Applications of Ferro Cement:

Due to the very high percentage of well distributed and continuously running steel reinforcement, the ferro cement behaves like steel plates. Its cracking resistance, ductility, impact and fatigue resistances are higher than that of normal concrete. The impermeability of ferro cement product is far superior than ordinary R.C.C. products.

Due to these properties the ferro cement can be used for the following purposes:

1. Ferro cement can be used successfully for casting domestic overhead tanks. These tanks being light and flexible can be transported and hoisted without difficulty. The inlet and out let connections also can be done easily with the help of modem adhesives like “m seal”. These tanks will be cheaper than any other type of material tanks.

2. These tank units can also be modified into silos for storing grains in villages. These tanks will help in preserving grains from moisture effect and rodents.

3. Similar ferro cement tanks can be used in villages as gas holding units in ‘Gobbar gas’ plants. With some modifications ferro cement tanks can also be used as septic tanks.

4. Due to the favourable properties of ferro cement, this material has been widely used for boat building in U.K., U.S. and New Zealand. It has been reported that 14 m long ferro cement boat weighs only 10% more than the wooden boats. Ferro-cement boats are found 300% cheaper than fibre reinforced concrete boats, 200% cheaper than steel boats and 35% cheaper than timber boats.

5. The cost of ferro cement is only about 10% of the cost of cast iron. Thus the use of ferro cement manhole covers is becoming very popular, where these manhole covers are not subjected to heavy vehicular traffic.

6. Ferro cement is becoming more popular material for pre-fabricated roof units. The folded plates of ferro cement being light can be advantageously used as prefabricated roof units. A 3 cm thick ferro cement folded plate with two layers of chicken wire mesh can be used safely over a span of 3.5 m. It can also be used for prefabricated channel units for roof construction.

7. Ferro cement being a light material, considerable reduction in self-weight of structure and foundation cost can be reduced to a great extent. A 30% reduction in dead weight on supporting structure, 15% saving in steel consumption and 10% saving in roof cost has been observed in USSR by the use of ferro cement.

8. Ferro cement is found most suitable material for the production of pressure pipes. It is much lighter than normal RCC pipes.

9. Ferro cement also is found suitable for casting curved benches for parks, gardens, and open cinema theatre. It can also be used to cast tree guards. They can be cast in two parts to facilitate their removal at a later data.

Advantages of Ferro Cement:

Following are the advantages of the ferro cement:

1. The construction technique of ferro cement is simple. It does not require skilled labour.

2. Complete or partial elimination of form work is possible.

3. Ferro cement construction is easily amenable to repairs in case of local damage due to abnormal loads as impact load.

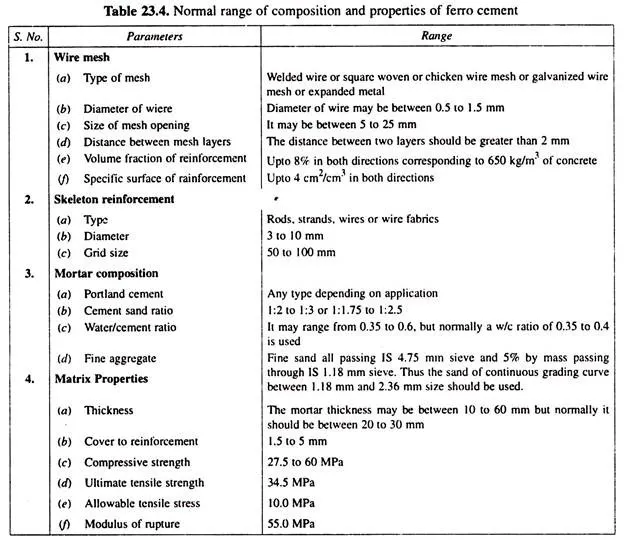

Summary of composition and properties of commonly used ferro cement are shown in Table 23.4 below:

Comments are closed.