Ferrocoment is a type of composite material in which cement and some kind of filler material called matrix is reinforced with the fibers. These fibers should be dispersed throughout the composite material and it results in a better performance as compared to the original material. The composite material to be used should be unique in the properties just like better resistance to cracking, higher compressive strength, higher tensile strength and good durability. The applications of ferrocement products includes water storage tanks, grain storage bins, boats, small ships, pipes, elements for roofing houses, canal lining elements and other utility products.

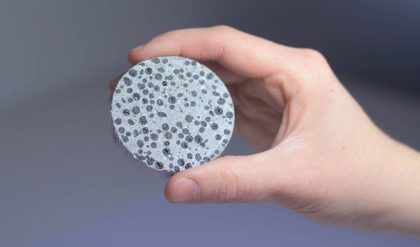

Figure showing Ferrocement products

Procedure

The procedure for ferrocement product is to prepare the skeleton framework onto which the wire mesh is properly fixed with the thin tie wire or sometimes it can be fixed with the welding connection. A minimum of two layers of wire mesh should be provided and depending upon the design of element, up to 12 layers can be used, with a maximum of 5 layers per cm of thickness.

The ingredients like cement, sand and additives are proportioned properly by taking weight of all those materials and then mixed dry, at last mixed with water. Firstly the stability of the framework should be checked. The mortar is applied to it with the help of hand and trowels and thoroughly worked in to the mesh which will close the voids.

If the thicker structures are to be made then the two stages are appeared. From one side the plastering to half thickness is carried out and should be allowed to cure for up to two weeks. Then the other side of the structure should be completed.

The compaction should be carried out by beating the mortar with the help of trowel or with the flat piece of wood. The minimum cover to the mortar should be 1.5 mm so that the care has to be taken not to leave any reinforcement exposed on the surface.

Each stage of plastering should be carried out preferably in dry weather without any kind of interruption and to be protected from the atmosphere (wind and sun). Ferrocement should be moist cured for a minimum of 14 days just like in the procedure of concrete construction.

Trusses and Rafters

Generally, clay tiled roofing is adopted for houses with the help of timber trusses or rafters as the supporting structures while the secondary members can be timber reapers. When the ferrocement trusses or rafters are used then it is found that they are better in performance as well durability as compared to the timber. Such products were free from the fire hazards and attacks from termite. As the cost of timber is increasing day by day the use of ferrocement has become popular for trusses and rafter and found to be even attractive material. Such types of materials are cheaper as compared to the timber material.

Ferrocement rafters

Ferrocement rafters are used for supporting the tiled roofing materials. Generally, rafters are spaced at the distance of 750-1000 mm approximately and in the span ranges from 3.6 to 6 m will have a conventional timber scantling of size 25 mm x 50 mm. therefore they are made to the profile of I section and then assembled together with the help of steel bolts and nuts. The conventional reapers which are spanning between the rafters can be replaced by the ferrocement trough units which can receive the country sides. Serving as the water proofing elements, the trough units provide good ceiling finish also. Such types of rafters can be mass production.

The calculated steel as reinforcement should be provided in the body of the rafter in addition to providing normal weld mesh and chicken mesh type distribution steel. The performance can be improved of such sections by stressing the welded mesh element on a long line stressing bed prepared for this purpose. The rafters can also be made on the long line stressing bed if the concrete cutting saws are available. The prestressing technology can also be used since it effectively prevent the cracks which may occur due to various reasons like handling stresses at early age.

Ferrocement Trusses

If the requirements are for some small housing schemes with lean-to roofs then monolithic ferrocement can be made in any desired shape or profile. Such type of trusses and their sections and reinforcement can be designed so that there will be match the loading requirements.

Ferrocement Roofs

Ferrocement roofs can be made in-situ or with the help of precast technology. Cast in situ products are helpful for free forms while the precast technology is appropriate for the modular and repetitive constructions.

Depending upon the design, ferrocement roofs can be made large span areas without any supporting structures and therefore it saves the cost and provides unobstructed covered areas. If the ferrocement surface is properly executed (complete cover of wire mesh, dense and smooth finish and crack sealed) then there will be no need to protect the surface and it saves the cost. Therefore it is advantages to applying the reflective coat on the outer surface so that solar heat absorption will be reduced.

Framed Ferrocement Roof

If the walls are created once the there is no need to provide the reinforced concrete ring beam since the roof is designed to clamp the walls together. Around the top and outer edge of the walls, a timber frame is fixed and the two tripod frames above the floor area. The surfaces described by these frames are looks like hyperbolic paraboloids and they are made up of a straight line. This simplifies the wire mesh fixing.

The mesh with the two to three layers are stretched over the frame and nailed or stapled onto it. The frame is needed to hold the mesh during construction only since the structure shall be self-supporting if it is plastered.

Reinforcing bars are fixed around the walls as well as along the folds of the roof. The roof is even plastered by a team on top forcing the mortar through the mesh. Another team below recovers the falling mortar to plaster the inside.

This curved roof system permits the wind to blow around smoothly and making it very suitable for hurricane-prone areas.

Attic type Ferrocement core units

This type of system consists of a three-dimensional ferrocement core unit of around 3 cm thickness. The weight of this core unit is 900 kg approximately and such core units are supported on the four columns constructed with precast technology and they are fixed with the in-situ concrete joints. To use as an emergency shelter such type of simple core units are used. Also, the designs of core units are made for more hazard-resistant and permanent element.

Figure showing method for Ferrocement product assembly

Comments are closed.