Meaning and Classification of Light Weight Concrete:

The self-weight of normal cement concrete varies from 2200 to 2600 kg/m3. This is one of the main disadvantages of conventional cement concrete as this heavy weight of concrete makes it uneconomical structural material. To increase the efficiency of concrete as a structural material attempts have been made to reduce the weight of normal cement concrete. A cement concrete having self-weight ranging from 300 kg/m3 to 1850 kg/m3 is called light weight concrete.

Classification:

The light weight concrete can be classified into the following groups, depending on the method of production:

1. Light Weight Aggregate Concrete:

This type of concrete is produced by using porous light weight aggregate of low specific gravity usually less than 2.6.

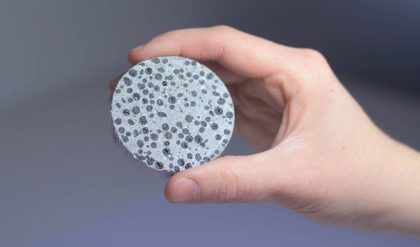

2. Aerated, Cellular, Foamed or Gas Concrete:

This type of concrete is produced by introducing larger voids with in the concrete or mortar. These voids should be clearly distinguished from the fine voids produced by air entrainment.

3. No Fines Concrete:

This type of concrete is produced by omitting the fine aggregate from the mix, which results in the large number of interstitial voids. In this concrete normal weight coarse aggregate is used.

In essence, the decrease in density of the concrete in each method is obtained by the presence of voids either in the mortar or in the aggregate or in the interstices between the particles of coarse aggregate. The presence of voids reduces the strength of light weight concrete in comparison to normal weight concrete. As stated above, in many applications high strength is not essential.

The light weight concrete provides good thermal insulation and has a satisfactory durability, but is not highly resistant to abrasion. Light weight concrete in general is more expensive than ordinary concrete. It requires more care in mixing, handling and placing than ordinary concrete.

The light weight concrete may also be classified according to its use as follows:

1. Structural light weight concrete.

2. Masonry light weight concrete or non-load bearing concrete.

3. Insulating concrete.

This classification of structural light weight concrete is based on a minimum strength:

1. Structural Light Weight Concrete:

The 28 day cylinder compressive strength of this concrete should not be less than 17 MPa. Its density should not exceed 1840 kg/m3. Usually it should be between 1400 1800 kg/m3.

2. Masonry Concrete:

The 28 day cylinder compressive strength of this concrete should be between 7 to 14 MPa. Its density should be between 500 to 800 kg/m3.

3. Insulating Concrete:

Its coefficient of thermal conductivity should be below 0.3 J/m2S°C/m. Its strength should be between 0.7 and 7 MPa and density generally lower than 800 kg/m3.

In recent years light weight concrete has become more popular due to the manifold advantages it offers over the conventional concrete. A better understanding and development of modern technologies have also helped in the promotion and use of light weight concrete. The light weight structural concrete, is lighter than conventional concrete, but at the same time strong enough to be used for structural purposes.

It combines the advantages of normal weight concrete and discards the disadvantages of normal concrete This type of light weight concrete has great future. Out of the main groups of light weight concrete the light weight aggregate concrete and aerated concrete are more often used than no fines concrete. Previously aerated concrete mainly was used for insulating purposes. Nowadays it is also used for structural purposes along with steel reinforcement.

The aerated concrete is more widely manufactured and used in Scandivian countries. In U.K. France, Germany and U.S. light weight aggregate concrete is widely manufactured and used due to the production of large scale artificial industrial light weight aggregate Now a days considerable varieties of industrial light weight aggregates of varying properties are available by different trade names.

Some of them are as follows:

(a) Aglite and Hadite (Expanded shale)

(b) Leca (Expanded clay)

(c) Lytag (Sintered pulverised fuel ash) etc.

The groups of light weight concrete are shown in Table 22.1.

Comments are closed.