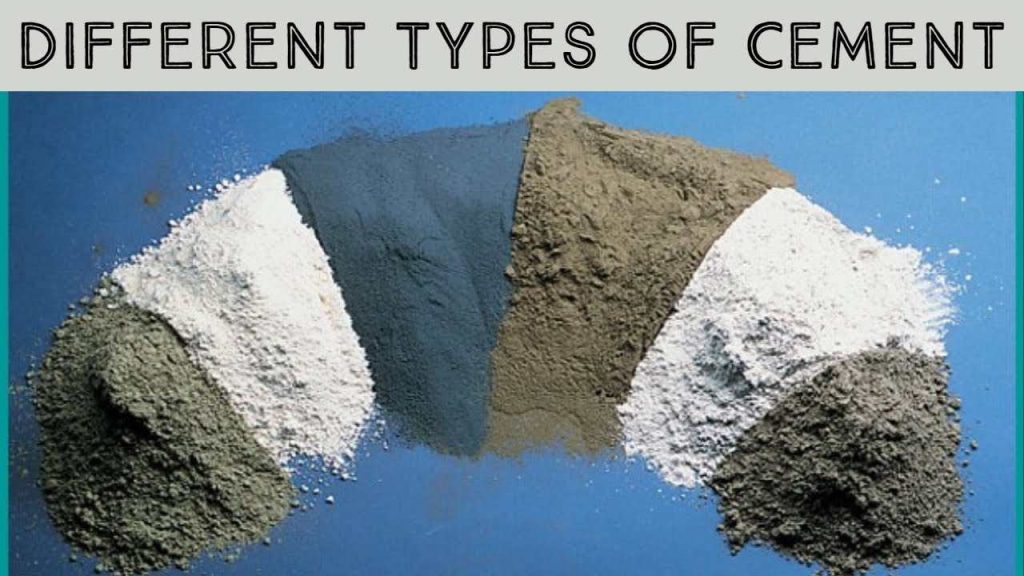

ASTM Specification C-150 provides standards for eight different types of Portland cement:

· Type I is a general-purpose cement used in a wide variety of project types, including buildings, bridges, floors, pavements, and precast concrete projects.

· Type IA is similar to type I but is used for projects requiring air-entrainment.

· Type II generates less heat, generates heat at a slower rate, and has moderate resistance to sulfate attack.

· Type IIA is identical to Type II but is used for projects requiring air-entrainment.

· Type III is a high early-strength cement that causes concrete to set and gain strength quickly. Type III cement is chemically and physically similar to Type I except that the particles are more finely ground.

· Type IIIA is a high early-strength cement used for projects requiring air-entrainment.

· Type IV develops strength at a slower rate than other cement types and produces lower levels of heat during hydration. It’s used for large-mass concrete structures from which there is little chance for heat to escape, such as dams.

· Type V is used only in concrete structures that will be exposed to severe attack by sulfates, typically in places where concrete is exposed to soil and groundwater with a high sulfate content.

ASTM C-1157 includes the following:

1. Type GU hydraulic cement is used for general construction.

2. Type HE is high early-strength cement.

3. Type MS is moderately resistant to attack from sulfates.

4. Type HS is highly resistant to attack from sulfates.

5. Type MH produces moderate levels of heat during hydration.

6. Type LH produces low levels of heat during hydration. This cement type can also be designed for low reactivity (Option R) with alkali-reactive aggregates.

Comments are closed